wanlink6200

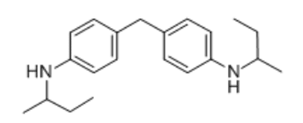

Product Name 4,4'-methylenebis[N-sec-butylaniline]

Code WANLINK®6200

Structure

Product Description

WANALINK® 6200 is the brand name of N,N’-bis(sec-butylamino) Diphenylmethane and the product is a liquid secondary diamine based on methylene dianiline. The alkyl groups improve the solubility of the diamine, allowing it to blend readily with almost any polyol or polyamine. WANALINK®6200 diamine enjoys commercial success in rigid and flexible foams, coatings, adhesives, sealants and elastomers and has also found use in spray polyurea formulations and a range of metal and concrete repair compounds.

Specification

|

Appearance |

Light Yellow to Dark Amber |

|

Purity% |

≥96.0 |

|

MDA Content% |

≤0.030 |

|

H2O% |

≤0.050 |

Application

WANALINKTM 6200 is a light yellow to dark amber liquid at room temperature. It is a liquid secondary diamine with lower activity. WANALINKTM 6200 is the brand name of 4,4’-bis(sec-butylamino) Diphenylmethane. It is a liquid secondary diamine. One of the atoms of hydrogen on each of the amine group is substituted by a secondary butyl group, so that the combination of an active hydrogen atom and a secondary butyl group in a confined space creates many unusual properties. The amine portion forms area linkages which affect the hard segment domains, while the butyl groups functions as inner plasticizer. Bonded to the polymer matrix, it neither leaches, nor bloom. The alkyl groups also improve the solubility of the diamine, allow it to blend readily with almost any polyol or polyamine. WANALINKTM 6200 can be applied in rigid and flexible foams, coatings, adhesives, sealants, and elastomers. Typical use levels are 1-5% of polyol. It can also be applied in spray polyurea, and a range of metal and concrete repair compounds.

Package

20 Kg Tinplate pails or 200 Kg Metal drum

Storage

Metal drum WANALINKTM 6200 should be stored in tightly closed containers with proper labels in a cool and well-ventilated warehouse away from all ignition sources. Eye contact, prolonged skin contact, and inhalation of vapor must be avoided. Do not take internally. Never Use welding or cutting equipment near the containers to prevent vapor explosion.

Shelf Life

Metal drum The shelf life is 12 months under recommended storage conditions.